RAG for Data Center Cleaning Protocols

AI-powered contamination control and equipment care to prevent hardware failures and optimize energy efficiency.

Introduction: Why Cleaning Protocols Matter More Than You Think

Data center cleaning isn't just about aesthetics—it's a critical operational discipline that directly impacts equipment reliability, energy efficiency, and uptime. Dust, particulates, and contamination cause 30% of all hardware failures and can increase cooling costs by 15-25%.

Yet managing cleaning protocols across thousands of equipment types, varying environmental conditions, and strict compliance requirements is extraordinarily complex. Retrieval-Augmented Generation (RAG) technology is transforming how data centers approach contamination control.

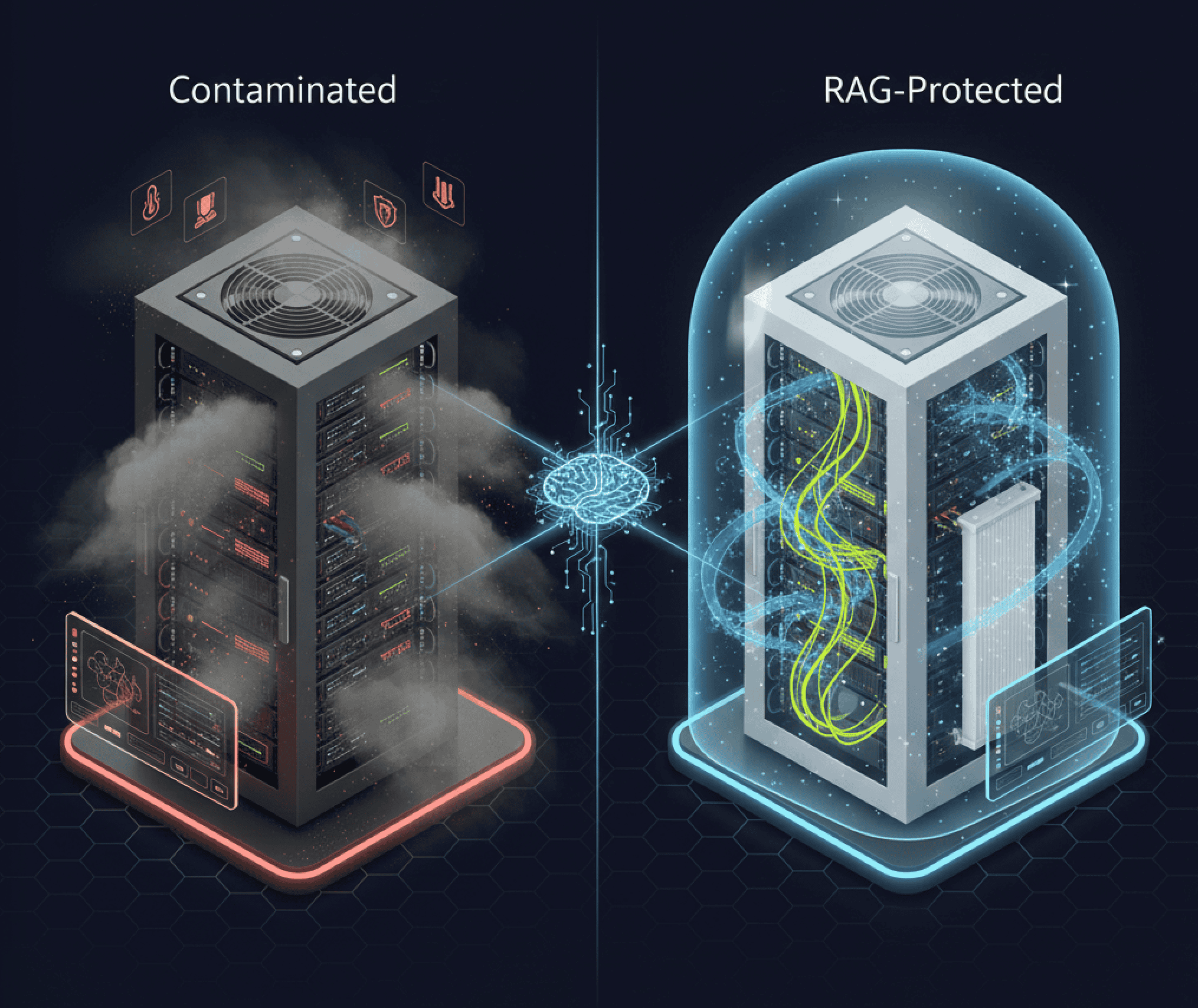

What is RAG (Retrieval-Augmented Generation)?

RAG is an AI architecture that combines large language models with your organization's specific knowledge base. For cleaning protocols, this means:

- Retrieves cleaning procedures from vendor manuals, OEM specifications, and environmental guidelines

- Augments responses with your facility's specific equipment inventory and conditions

- Generates precise, compliant cleaning instructions for any scenario

Unlike generic AI responses, RAG ensures every cleaning recommendation is backed by actual documentation and tailored to your environment.

The Hidden Costs of Poor Cleaning Practices

Industry Research & Statistics

| Impact Area | Cost of Inadequate Cleaning |

|---|---|

| Equipment failure from contamination | 30% of all hardware failures |

| Increased cooling costs from dust buildup | 15-25% higher energy consumption |

| Warranty voidance from improper cleaning | $50,000+ per incident |

| Unplanned downtime from contamination | 2-5 hours monthly average |

Real-World Impact Data

- ASHRAE research shows that particulate contamination above 50 μg/m³ correlates with 40% higher failure rates

- Uptime Institute reports that 65% of data centers have inadequate contamination monitoring

- IBM studies found that proper cleaning reduces server failure rates by 28%

- Organizations implementing RAG for cleaning protocols report 20-30% reduction in contamination-related incidents

Why Traditional Cleaning Approaches Fail

Challenge 1: Equipment Diversity

A typical enterprise data center contains:

- 15-30 different server vendors

- 50+ unique hardware configurations

- Various storage systems, networking equipment, and power systems

- Each with specific cleaning requirements and restrictions

The Problem: Technicians cannot memorize cleaning procedures for thousands of equipment variations. Using wrong cleaning materials can void warranties, damage components, or create safety hazards.

Challenge 2: Environmental Variability

Cleaning requirements vary dramatically based on:

- Geographic location (coastal, industrial, urban)

- Seasonal factors (humidity, pollen, temperature)

- Facility age and air handling systems

- Local regulations and standards

The Problem: Static cleaning schedules don't adapt to changing conditions, leading to either over-cleaning (wasted resources) or under-cleaning (contamination risks).

Challenge 3: Compliance Complexity

Data centers must comply with:

- OEM warranty requirements

- Environmental health and safety regulations

- Industry standards (ASHRAE, ISO 14644)

- Customer contractual obligations

The Problem: Tracking and ensuring compliance across all requirements is nearly impossible with manual processes.

How RAG Transforms Cleaning Protocol Management

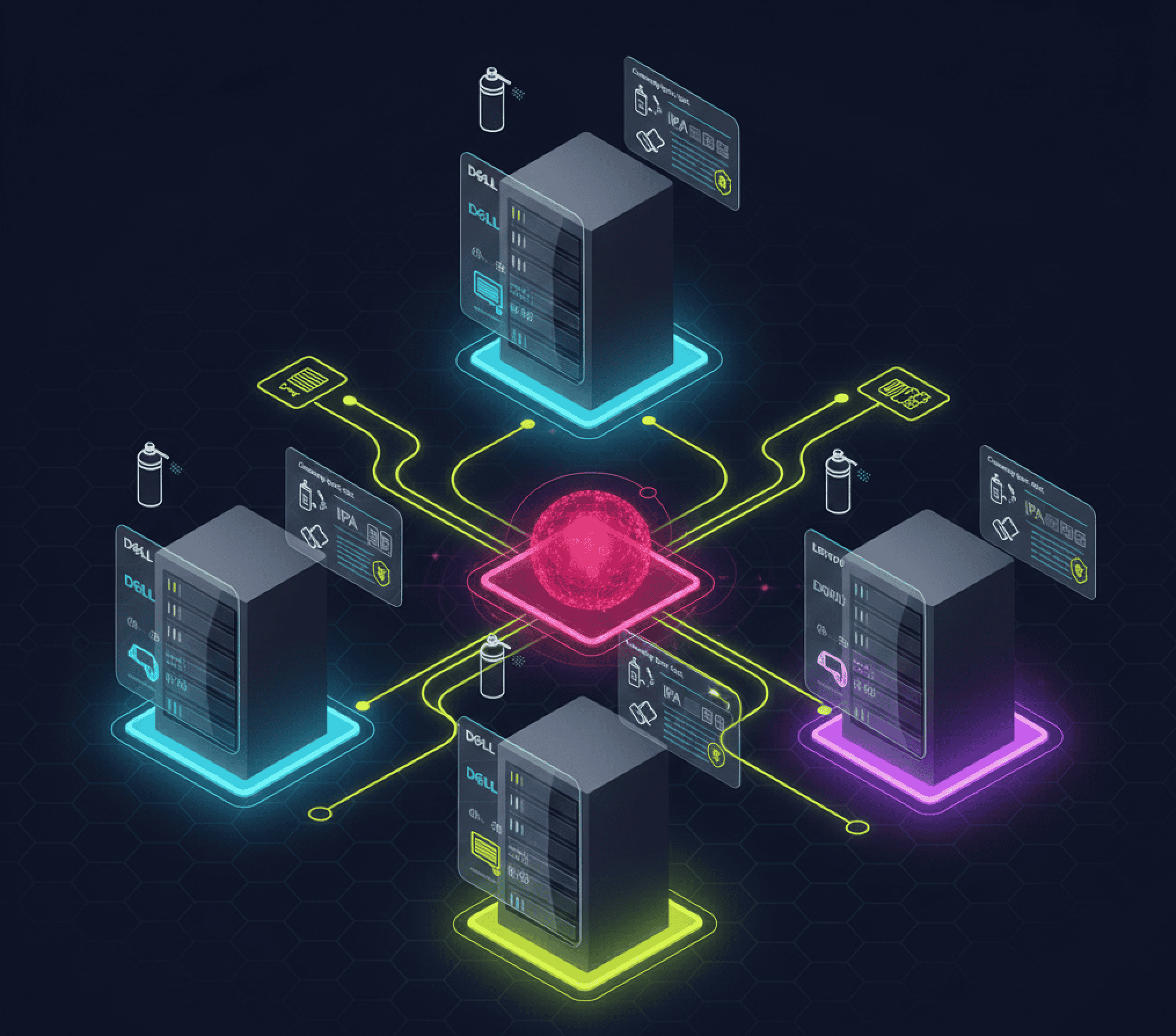

Use Case 1: Equipment-Specific Cleaning Procedures

Scenario: Quarterly deep clean scheduled for server racks containing mixed Dell, HPE, and Lenovo hardware.

RAG Query:

"Quarterly deep clean for Racks A1-A12. Equipment mix: Dell PowerEdge R750 (24 units),

HPE ProLiant DL380 Gen10 (18 units), Lenovo ThinkSystem SR650 (12 units).

Provide approved cleaning procedures."

RAG Response:

## Quarterly Deep Clean: Racks A1-A12

### Pre-Cleaning Requirements

- [ ] Schedule maintenance window (minimum 4 hours)

- [ ] Notify affected customers per SLA requirements

- [ ] Verify backup systems operational

- [ ] Prepare ESD-safe cleaning supplies

---

### Dell PowerEdge R750 (24 units)

**Reference:** Dell Datacenter Cleaning Guidelines, Rev 3.2

**Approved Cleaning Materials:**

- Compressed air: Max 30 PSI, CFC-free

- Wipes: IPA-based (70% isopropyl alcohol), lint-free

- Vacuum: ESD-safe, HEPA filtered

**Procedure:**

1. Power verification (do not clean powered units)

2. External dust removal with HEPA vacuum

3. Air filter inspection (replace if >60% blocked)

4. Fan area cleaning with compressed air (short bursts only)

5. Connector inspection and cleaning with IPA wipes

**⚠️ Restrictions:**

- DO NOT use water-based cleaners

- DO NOT remove CPU heatsinks (thermal paste warranty issue)

- Avoid direct air on spinning drives

**Post-Cleaning:**

- Document serial numbers cleaned

- Log filter replacement if performed

- Verify power-on successful

---

### HPE ProLiant DL380 Gen10 (18 units)

**Reference:** HPE Server Maintenance Guide, Document P00001-001

**Approved Cleaning Materials:**

- Compressed air: HPE-approved only (part #123456)

- Cleaning solution: HPE System Cleaning Agent

- Cloths: Non-abrasive, lint-free microfiber

**Procedure:**

1. Remove from rack if deep cleaning required

2. Ground yourself and equipment

3. Vacuum external surfaces first

4. Use short bursts of compressed air for internal areas

5. Clean ventilation openings thoroughly

6. Inspect and clean memory slot areas

**⚠️ Restrictions:**

- DO NOT use standard compressed air (may contain oils)

- DO NOT clean with unit powered (automatic shutdown risk)

- Avoid cleaning optical drive lens unless visibly dirty

---

### Lenovo ThinkSystem SR650 (12 units)

**Reference:** Lenovo Maintenance Manual, Chapter 8

**Approved Cleaning Materials:**

- Compressed air: Oil-free, <40 PSI

- Isopropyl alcohol: 99% concentration

- Anti-static brush: Soft bristle only

**Procedure:**

1. Discharge static before touching equipment

2. Remove air baffles for internal cleaning

3. Clean heat sinks with compressed air

4. Wipe down all surfaces with IPA

5. Reinstall air baffles - verify proper seating

**⚠️ Restrictions:**

- DO NOT remove heat sinks without thermal paste replacement

- DO NOT bend air baffles during removal

- Keep cleaning solutions away from display panels

---

### Quality Verification Checklist

- [ ] Visual inspection: No visible dust accumulation

- [ ] Temperature check: Within 2°C of pre-cleaning baseline

- [ ] System logs: No cleaning-related errors

- [ ] Photo documentation: Before/after for records

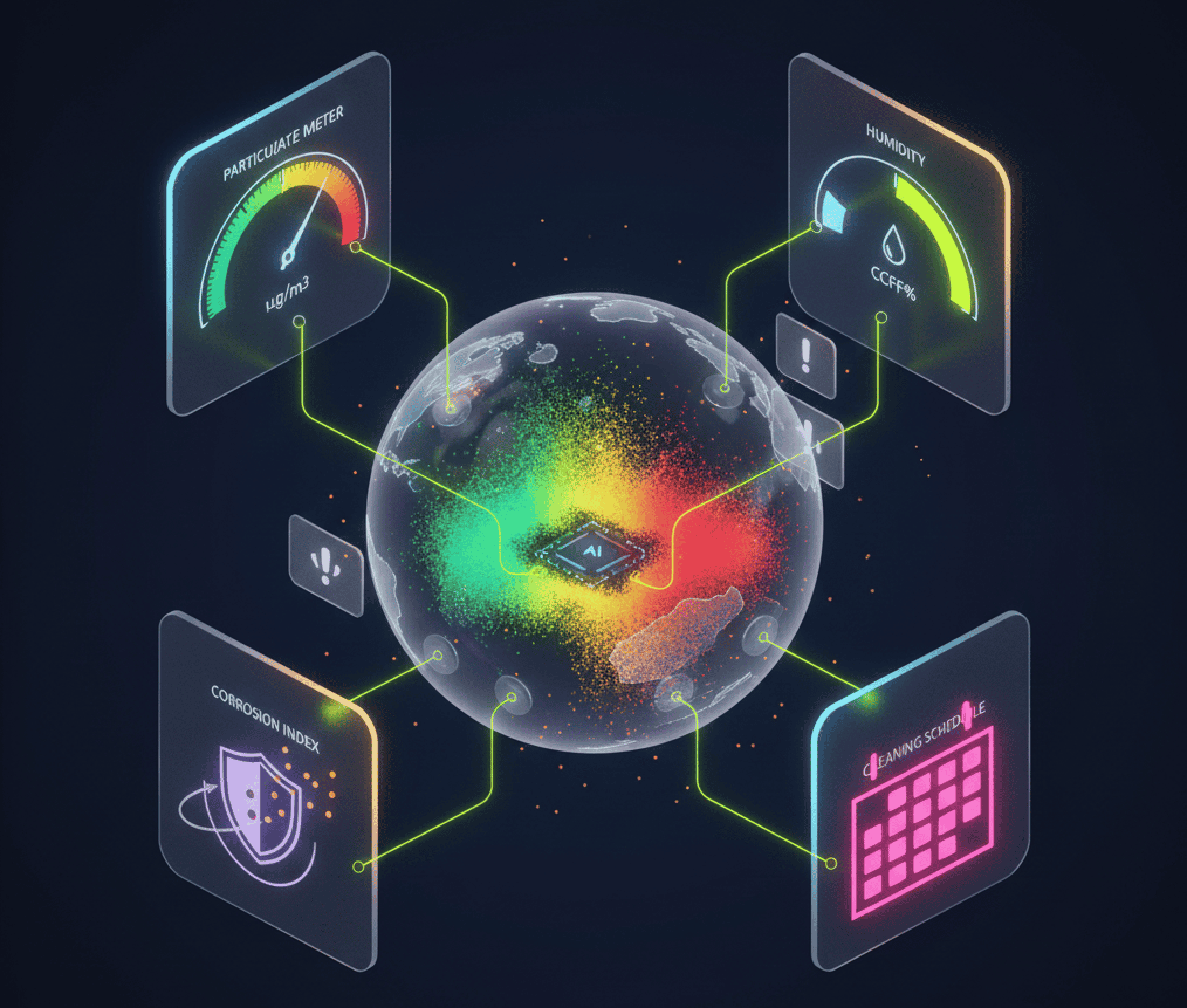

Use Case 2: Environmental Factor-Based Cleaning

Scenario: Data center located in coastal industrial zone showing elevated particulate levels in cooling system.

RAG Query:

"Facility: Singapore DC-2, coastal location, 500m from industrial port.

Air quality sensors showing 85 μg/m³ particulate (normal: 50 μg/m³).

Recommend cleaning frequency adjustments."

RAG Response:

## Environmental Cleaning Assessment: Singapore DC-2

### Current Contamination Analysis

| Parameter | Normal Range | Current Reading | Status |

|-----------|-------------|-----------------|--------|

| Particulate (PM10) | < 50 μg/m³ | 85 μg/m³ | ⚠️ ELEVATED |

| Salt content | < 1 mg/m³ | 2.3 mg/m³ | ⚠️ HIGH |

| Humidity | 40-55% | 62% | ⚠️ ELEVATED |

| Corrosive gases | < 5 ppb | 8 ppb | ⚠️ ELEVATED |

### Risk Assessment

**Contamination Class:** ISO 14644-1 Class 8 (elevated from normal Class 7)

**Primary Concerns:**

1. **Salt Corrosion:** Coastal proximity + industrial emissions accelerate corrosion

2. **Conductive Particulate:** Industrial dust may cause electrical shorts

3. **Moisture Interaction:** High humidity + salt creates aggressive corrosion environment

**Equipment at Risk:**

- Exposed connectors and contact points

- Power supply units (PSU corrosion)

- Cooling fan bearings

- Memory module contacts

### Recommended Cleaning Frequency Adjustments

| Equipment Category | Standard Frequency | Recommended Adjustment |

|-------------------|-------------------|----------------------|

| Server externals | Quarterly | Monthly |

| Air filters | Quarterly | Monthly |

| Cooling coils | Semi-annual | Quarterly |

| Cable management | Annual | Semi-annual |

| Floor cleaning | Weekly | 2x weekly |

| CRAC/CRAH units | Quarterly | Monthly |

### Additional Protocols Required

**1. Enhanced Filtration**

- Upgrade to MERV 14 filters (currently MERV 11)

- Add activated carbon pre-filters for gas removal

- Estimated cost: $12,000/year additional

**2. Corrosion Prevention**

- Apply conformal coating to vulnerable PCBs during next maintenance

- Install vapor corrosion inhibitor (VCI) in critical cabinets

- Schedule semi-annual connector treatment

**3. Humidity Control**

- Target: 45% RH (reduce from current 62%)

- Increase dehumidifier runtime

- Check door seals for infiltration

**4. Air Quality Monitoring**

- Deploy continuous particulate monitoring (currently periodic)

- Set alerts at 70 μg/m³ threshold

- Weekly trend analysis required

### Cost-Benefit Analysis

| Investment | Annual Cost | Risk Reduction | ROI |

|------------|------------|----------------|-----|

| Increased cleaning | $45,000 | 60% fewer failures | 340% |

| Enhanced filtration | $12,000 | 25% fewer failures | 280% |

| Corrosion prevention | $8,000 | 40% fewer corrosion incidents | 420% |

| **Total** | **$65,000** | **Combined: 75% risk reduction** | **350%** |

### Compliance Note

Per ASHRAE TC 9.9, gaseous contamination limits:

- Copper corrosion: < 300 Å/month (action required at current levels)

- Silver corrosion: < 200 Å/month (monitoring recommended)

**Recommended Action:** Schedule corrosion coupon testing within 30 days.

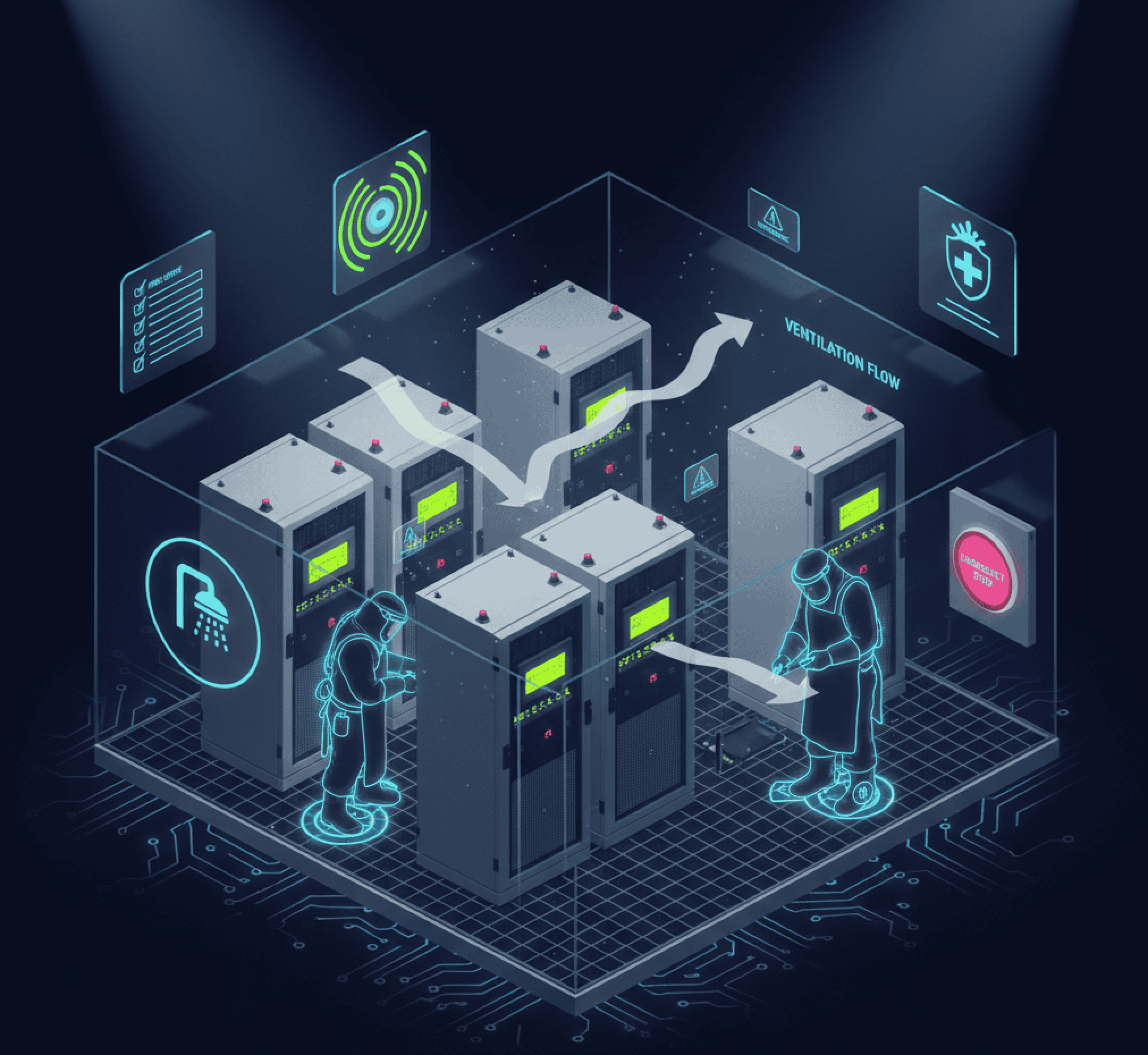

Use Case 3: High-Risk Area Cleaning

Scenario: Scheduled cleaning for Battery Backup Room with 99.99% uptime requirement.

RAG Query:

"Schedule cleaning for Battery Backup Room B3. Contains 4x Eaton 9395 UPS units,

critical 99.99% uptime SLA. What are the safety requirements and procedures?"

RAG Response:

## High-Risk Area Cleaning: Battery Backup Room B3

### ⚠️ CRITICAL SAFETY AREA ⚠️

**Uptime Requirement:** 99.99% (max 52.6 minutes downtime/year)

**Equipment:** 4x Eaton 9395 UPS (480V, 225kVA each)

**Risk Level:** HIGH - Electrical + Chemical Hazards

---

### Pre-Cleaning Safety Requirements

**1. Personnel Qualifications**

- [ ] NFPA 70E electrical safety certification

- [ ] UPS manufacturer training (Eaton-specific preferred)

- [ ] First aid / CPR certification

- [ ] Minimum 2 years battery room experience

**2. Required PPE**

| Item | Specification | Purpose |

|------|--------------|---------|

| Safety glasses | ANSI Z87.1, splash-resistant | Acid splash protection |

| Face shield | Full coverage | Acid splash protection |

| Gloves | Rubber, acid-resistant | Chemical handling |

| Apron | PVC or rubber | Chemical protection |

| Steel-toe boots | Electrical hazard rated | Electrical + physical |

**3. Safety Equipment On-Site**

- [ ] Eye wash station verified operational (test within 24 hours)

- [ ] Emergency shower accessible (< 10 seconds travel)

- [ ] Acid spill neutralization kit available

- [ ] Fire extinguisher (Class C) within reach

- [ ] First aid kit with burn treatment supplies

**4. Environmental Monitoring**

- [ ] Hydrogen gas detector active (alarm at 1% concentration)

- [ ] Ventilation system operational

- [ ] Temperature monitoring active

---

### Cleaning Procedure

**Phase 1: Preparation (Day Before)**

- Notify Operations of scheduled maintenance

- Verify redundant power path operational

- Test transfer to bypass mode (if cleaning requires)

- Pre-position cleaning materials outside room

- Review emergency procedures with team

**Phase 2: Safety Setup (30 minutes before)**

1. Two-person rule: Never work alone in battery room

2. Establish communication with control room

3. Verify hydrogen levels < 0.5% (normal)

4. Check emergency exit path clear

5. Review hot work permit if applicable

**Phase 3: UPS Surface Cleaning**

*Per Eaton 9395 Maintenance Manual, Section 8.4:*

**Approved Materials:**

- Damp cloth (water only) for exterior surfaces

- Dry, lint-free cloth for displays and panels

- Approved insulating cleaner for electrical areas

**DO NOT USE:**

- Compressed air near battery terminals

- Solvents or chemical cleaners

- Abrasive materials

- Excessive water

**Procedure:**

1. Clean front panels and displays (dry cloth only)

2. Remove dust from ventilation grilles (soft brush)

3. Wipe cabinet exterior surfaces (damp cloth, minimal water)

4. Inspect and clean air intake filters

5. Document any visible damage or corrosion

**Phase 4: Battery Cleaning**

⚠️ **EXTREME CAUTION - HIGH VOLTAGE + CHEMICAL HAZARD**

**Battery String Cleaning (powered state):**

1. Visual inspection only - do not touch terminals

2. Check for corrosion or electrolyte leakage

3. Clean tops of batteries with DRY cloth only

4. Record any anomalies for maintenance team

**If Corrosion Present:**

- Do NOT clean corrosion during routine cleaning

- Document location and severity

- Schedule dedicated battery maintenance

- Notify facilities manager immediately

**Phase 5: Floor and Room Cleaning**

1. Sweep floor with soft-bristle broom (avoid static)

2. Mop with approved anti-static floor cleaner

3. Clean ventilation grilles and diffusers

4. Check and clean smoke detector housings

5. Inspect and clean emergency lighting

---

### Optimal Scheduling Windows

**Lowest Risk Times (based on facility load patterns):**

- Tuesday-Thursday: 2:00 AM - 5:00 AM local

- Avoid: Month-end processing periods

- Avoid: Major customer batch job windows

**Required Coordination:**

- [ ] 48-hour advance notice to Operations

- [ ] Customer notification per SLA (if outage risk)

- [ ] Security escort for contractors

- [ ] Facilities manager on-call during cleaning

---

### Emergency Procedures

**Acid Spill:**

1. Evacuate non-essential personnel

2. Increase ventilation

3. Apply neutralizing agent (sodium bicarbonate)

4. Do NOT use water on large spills

5. Contact hazmat response if >1 liter

**Hydrogen Alarm:**

1. Evacuate room immediately

2. Increase ventilation to maximum

3. Do NOT operate electrical switches

4. Contact facilities emergency line

5. Do NOT re-enter until levels < 0.5%

**Electrical Incident:**

1. Do NOT touch victim if still in contact

2. De-energize if possible (emergency stop)

3. Call emergency services

4. Administer first aid when safe

5. Notify management immediately

---

### Post-Cleaning Documentation

- [ ] Cleaning checklist completed and signed

- [ ] Photos of any issues discovered

- [ ] Hydrogen levels documented (start/end)

- [ ] Temperature readings recorded

- [ ] Battery visual inspection log

- [ ] Anomaly report (if applicable)

- [ ] Next cleaning date scheduled

Implementation Architecture for Cleaning RAG

System Components

┌────────────────────────────────────────────────────────────┐

│ Cleaning Protocol RAG System │

├────────────────────────────────────────────────────────────┤

│ │

│ ┌─────────────────┐ ┌─────────────────┐ │

│ │ Document │ │ Environmental │ │

│ │ Repository │ │ Sensors (IoT) │ │

│ │ - OEM Manuals │ │ - Particulate │ │

│ │ - Safety SOPs │ │ - Humidity │ │

│ │ - Compliance │ │ - Temperature │ │

│ └────────┬────────┘ └────────┬─────────┘ │

│ │ │ │

│ ▼ ▼ │

│ ┌─────────────────────────────────────────┐ │

│ │ Vector Database │ │

│ │ (Embeddings + Real-time Data) │ │

│ └────────────────┬────────────────────────┘ │

│ │ │

│ ▼ │

│ ┌─────────────────────────────────────────┐ │

│ │ RAG Engine │ │

│ │ Query → Retrieve → Augment → Generate │ │

│ └────────────────┬────────────────────────┘ │

│ │ │

│ ▼ │

│ ┌─────────────────────────────────────────┐ │

│ │ Output Channels │ │

│ │ - Mobile App (technician) │ │

│ │ - Work Order System (CMMS) │ │

│ │ - Scheduling Dashboard │ │

│ │ - Compliance Reports │ │

│ └─────────────────────────────────────────┘ │

│ │

└────────────────────────────────────────────────────────────┘

Data Sources for Indexing

-

Vendor Documentation

- Equipment cleaning specifications

- Approved materials lists

- Warranty condition requirements

- Safety data sheets (SDS) for chemicals

-

Industry Standards

- ASHRAE TC 9.9 contamination guidelines

- ISO 14644 cleanroom standards

- NFPA electrical safety codes

- OSHA cleaning chemical regulations

-

Environmental Data

- Real-time air quality sensors

- Historical contamination trends

- Weather and seasonal patterns

- Geographic contamination profiles

-

Operational Records

- Past cleaning schedules and outcomes

- Contamination incident reports

- Equipment failure root cause analyses

- Compliance audit findings

ROI Analysis: Cleaning Protocol RAG

Cost Savings Breakdown

| Category | Annual Savings |

|---|---|

| Reduced contamination-related failures | $180,000 |

| Optimized cleaning schedules | $45,000 |

| Avoided warranty voidance | $75,000 |

| Reduced compliance violations | $30,000 |

| Improved energy efficiency | $60,000 |

| Total Annual Savings | $390,000 |

Implementation Investment

| Component | Cost |

|---|---|

| RAG platform setup | $30,000 |

| Document processing | $15,000 |

| IoT sensor integration | $25,000 |

| Training and rollout | $10,000 |

| Total Investment | $80,000 |

ROI Summary

- Payback Period: 3 months

- First Year ROI: 387%

- 3-Year NPV: $950,000

Best Practices for Implementation

1. Start with High-Risk Equipment

- Battery rooms and UPS systems

- Cooling infrastructure

- High-density compute areas

2. Integrate Environmental Monitoring

- Connect air quality sensors to RAG system

- Enable dynamic schedule adjustments

- Set up automated alerts

3. Build Compliance into the System

- Track all cleaning activities automatically

- Generate audit-ready reports

- Maintain full documentation trail

4. Enable Mobile Access

- Field technicians need real-time guidance

- Photo documentation integration

- Offline capability for restricted areas

Conclusion

RAG-powered cleaning protocols represent a fundamental shift from reactive, schedule-based cleaning to intelligent, condition-based contamination control. By connecting AI to your facility's specific documentation and real-time environmental data, you can:

- Reduce contamination-related failures by 60-75%

- Optimize cleaning schedules based on actual conditions

- Ensure OEM compliance for all equipment types

- Maintain complete audit documentation automatically

In an industry where a single contamination incident can cost hundreds of thousands in equipment damage and downtime, intelligent cleaning protocols aren't optional—they're essential.

Frequently Asked Questions

How does RAG handle different vendor requirements?

RAG indexes all vendor documentation and retrieves the correct procedures based on your specific equipment inventory. Conflicting requirements are flagged for human review.

Can RAG adapt cleaning schedules in real-time?

Yes, when integrated with environmental sensors, RAG can recommend schedule adjustments based on actual contamination levels rather than fixed calendars.

What about cleaning chemicals and safety data?

RAG indexes Safety Data Sheets (SDS) and ensures cleaning material recommendations comply with safety requirements and vendor approvals.

How do we maintain the knowledge base as equipment changes?

Automated document ingestion pipelines can monitor vendor portals for updates and flag new equipment additions for documentation indexing.

Last Updated: January 2026

Keywords: data center cleaning, contamination control, RAG cleaning protocols, equipment maintenance, air quality monitoring, cleanroom standards, ASHRAE compliance, data center dust removal, server cleaning procedures, environmental monitoring